From the perspective of panels.

Today we think about why everyone likes custom furniture. Do you know about what kinds of panels exist and how to select them? First, from the perspective of its components, the materials include panels, hardware, connectors, etc. We can further divide the services into design, production (processing), installation, and after-sales. Any problem in any link may affect the final product effect. Next, I will analyze the perspective of panels. I hope everyone who reads this article gains something and continues reading with me.

The kinds of panels are various.From the perspective of panels, first, we need to understand their importance. Let’s consider the core position panels hold in furniture: Panels form the skeleton and skin of custom furniture. They account for more than 60% of the cost and act as decisive factors for environmental protection, durability, and aesthetics.

Panels consist of base materials and surfaces. The surface forms the outer layer, which beautifies the piece, while the base material forms the inner layer. The base material determines the quality of a panel.

The market offers six types of panels: plywood, particleboard, medium-density fiberboard, blockboard, laminated board, and OSB.How should we select?

1.Particleboard

Particleboard is between plywood and medium-density fiberboard, with balanced performance, and is widely used in custom furniture.

2.Medium-density fiberboard

Medium-density fiberboard is made by grinding wood into powder and pressing it under high pressure with glue. According to the density, it is divided into high, medium, and low-density fiberboards.

Compared with plywood, its disadvantages are that it is not moisture-proof and prone to swelling and deformation when exposed to water vapor, so it is not suitable for use in bathrooms and other places prone to moisture. It has poor load-bearing capacity and is not suitable for use as a cabinet body. However, due to its fine particles, it has strong plasticity and a smooth surface, making it suitable for backboards and cabinet doors.

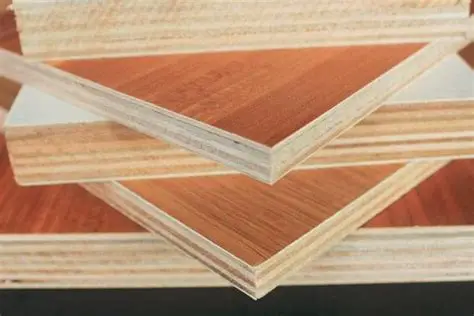

3. plywood

Plywood is also called multi-layer board, three-ply board, or nine-millimeter board. Its advantages are moisture-proof, pressure-resistant, and anti-deformation, with excellent load-bearing capacity. It is used in cabinets, bathroom cabinets, etc.

4. Blockboard

Also known as fine wood board, wood core board, woodwork board, or MDF board, it is mainly composed of board cores and thin boards. The board core is made of small wooden strips. The thin boards and board cores are glued and pressed to form blockboard.

5. Laminated board

Also called solid wood composite board or solid wood laminated board, it is made by gluing wooden boards together. The quality of this board mainly depends on the type of wood. However, since it is solid wood, it is not moisture-proof and is not suitable for bathrooms and kitchens. Among these boards, it is the closest to solid wood but cheaper, and can be used to make ordinary furniture.

6. OSB

OSB is generally imported from Europe. It is made by pressing large pieces of pure wood into oriented structural flakes, which are arranged in a crisscross pattern. The overall structure is tight and solid. The use of glue is strict, and it has good stability, nail-holding capacity, and toughness, and is not prone to cracking and deformation. It is a popular board for European homes and is also widely used in building materials.

In China, it is often used in high-end hotels or office buildings, but less in home decoration.

In real life, for full-house custom furniture, different materials are often used according to the application. Each material has its own value, and only by using them comprehensively can the overall effect be achieved.Now that you know the types of panels, you should know how to select?